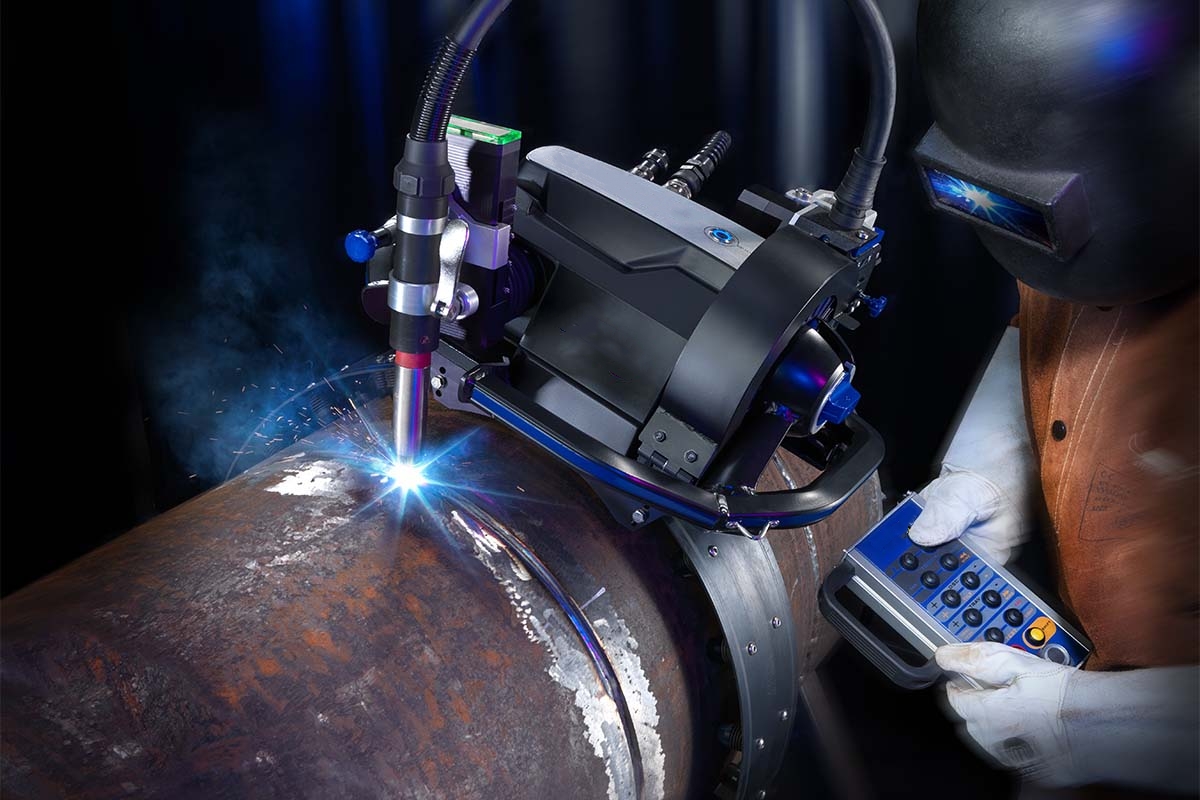

The KHPP Magnetic Type Orbital Welder is a customized machine, which is used for fabricated tube orbital welding projects - the pipe is fixed, welding carriage do all-position welding around the tube with the efficiency-cost MIG welding process. Suiting for large sizes tube Diameter≥140mm (≥5 inch), thickness 4 - 60mm.

KHPP could solve the issue of operator error in gas tungsten arc welding(GMAW/MIG/MAG).

KHPP is composed of the power supply with integrated computer control and the welding head.

KHPP could process carbon steel, stainless steel , alloy steel, etc.

KHPP Mainly used in oil, gas, water treatment industry, petrochemical industry, chemical industry, construction machinery, power plant and other industries.

KHPP could be used for Tube to tube, tube to elbow, tube to neck flange, tube to Tee joint, tube to concentric reducer and so on, with wire feeding.

Features1.To solve the issue of operator error in GMAW / MIG / MAG. PLC-controlled process runs with little intervention from the operator.

2.Magnetic Type carriage - can run around the tubes for doing all-position welding work.

3.OSC/AVC functions - with oscillation OSC and arc voltage control AVC.

4.To guarantee high quality repeatable welding. a successful programming monitors variables and performs periodic samples during its test welding. LCD touch screen, easy to input.

5.Intelligent welding . 100 successful programming stored in PLC, just pick one.

6.High productivity. 2-3 times higher than conventional MIG welding.

7.10 hours continuous welding. qualified welding torch and power and water cooling system make it.

8.Car-integrated design, freedom of movement.

9.Small space of scientific design

Welding Product